2026 Top Uses for Stainless Steel Woven Wire Mesh?

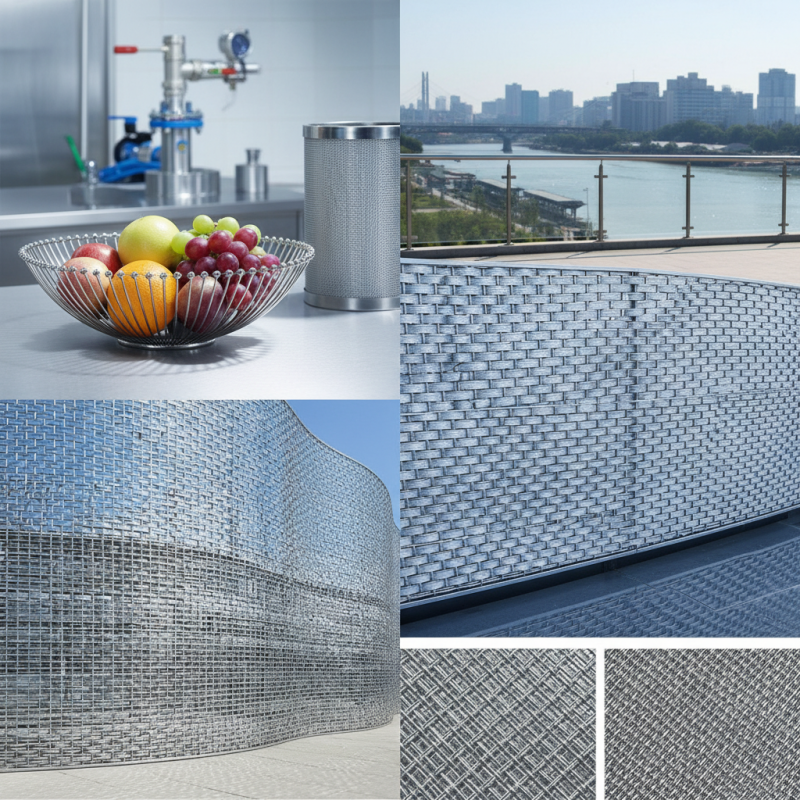

stainless steel woven wire mesh is incredibly versatile. It finds applications across various industries due to its durability and strength. The unique properties of this material allow for innovative designs and solutions.

In 2026, we will explore the top uses for stainless steel woven wire mesh. This material is not only functional but also aesthetically pleasing. From architecture to food production, the possibilities are extensive. Each use highlights different features of this excellent material.

Despite its advantages, challenges exist. Sizing and weaving methods can impact the mesh's effectiveness. It is crucial to choose the right specifications for each application. Reflecting on these factors enhances the overall utility of stainless steel woven wire mesh.

Key Characteristics of Stainless Steel Woven Wire Mesh

Stainless steel woven wire mesh offers remarkable characteristics that make it highly versatile. Its corrosion resistance is a standout feature. This property allows it to thrive in both indoor and outdoor environments. Additionally, the mesh is strong and resilient. It can withstand high levels of stress without compromising its structural integrity. These qualities make it ideal for various applications.

The woven design enhances flexibility. It allows for easier manipulation and installation. In industries like construction and agriculture, this adaptability is crucial. However, there are practical concerns to consider. While the mesh is durable, its performance can vary with different grades of stainless steel. Selecting the appropriate type is essential for achieving desired outcomes.

Aesthetically, stainless steel woven wire mesh provides a modern look. It complements various architectural styles. However, not everyone appreciates its appearance or cost. These aspects can lead to hesitation in choosing it over other materials. Users should weigh the advantages and disadvantages carefully to make informed decisions.

2026 Top Uses for Stainless Steel Woven Wire Mesh

| Use Case | Industry | Key Characteristics | Advantages |

|---|---|---|---|

| Filtration | Chemical Processing | Corrosion Resistance, High Strength | Durable and Long Lasting |

| Architectural Applications | Construction | Aesthetic Appeal, Flexibility | Versatile Design Options |

| Safety Screens | Manufacturing | High Tensile Strength | Improved Safety and Protection |

| Cages and Enclosures | Agriculture | Durable and Lightweight | Long Service Life |

| Sieve and Grading | Mining | Precision Mesh Size | Consistency in Results |

Common Industrial Applications of Stainless Steel Woven Wire Mesh

Stainless steel woven wire mesh is widely recognized for its strength and versatility. Its common industrial applications span multiple sectors. In the automotive industry, for example, it is used for filtration systems. Reports show that around 25% of industrial filters utilize woven wire mesh. This enhances efficiency and contributes to air quality.

In food processing, stainless steel mesh plays a critical role. It meets hygiene standards while ensuring durability. Approximately 30% of food manufacturers rely on this material for sorting and sieving. It is essential for maintaining food safety. However, some manufacturers struggle with sourcing high-quality mesh that meets all safety criteria.

Another significant use is in construction and architecture. Stainless steel woven wire mesh provides both aesthetic and functional benefits. It can enhance the structural integrity of buildings. Reports indicate a growing interest, with a 15% increase in mesh applications in architectural designs. Yet, some projects face challenges in integrating mesh seamlessly with other materials. This area requires ongoing adjustment and improvement.

Benefits of Using Stainless Steel Woven Wire Mesh in Construction

Stainless steel woven wire mesh is becoming a popular choice in construction. Its durability powers various applications, from safety barriers to decorative facades. The mesh resists corrosion, which makes it ideal for outdoor projects. This benefit leads to reduced maintenance costs over time.

The ability of stainless steel woven wire mesh to withstand harsh environments proves valuable. Structures in coastal areas benefit from this feature. The mesh maintains its integrity against salt and moisture. However, some may overlook its aesthetic appeal, considering function only. This can limit creative designs in architecture.

Tips: When choosing wire mesh, consider the weave type. Different designs serve distinct purposes. Test samples before purchase, ensuring they meet your needs. Evaluate how light passes through the mesh; this impacts visibility and ambiance. Finding the right balance between utility and beauty is essential.

Innovative Uses of Stainless Steel Woven Wire Mesh in Art and Design

Stainless steel woven wire mesh is transforming the art and design landscape. Artists are discovering its versatility. This material adds a unique texture to sculptures. Its durability ensures that outdoor installations withstand the elements. The mesh catches light in intriguing ways, creating dynamic shadows.

In interior design, the uses are equally innovative. Architects incorporate stainless steel mesh in partitions and railings. It provides both privacy and openness. The woven pattern creates an elegant aesthetic. Gallery spaces often use this mesh to hang artwork, allowing visibility from various angles.

However, challenges remain. The rigidity of stainless steel can limit creativity. Artists sometimes struggle with how to manipulate its structure. Finding the right balance between form and function is essential. Some designs may feel cold or uninviting. It’s important to reflect on the emotional impact of materials used in art.

Future Trends in Stainless Steel Woven Wire Mesh Technology and Applications

The future of stainless steel woven wire mesh technology is promising. This material is gaining traction in industries from construction to filtration. Its durability and corrosion resistance make it an ideal choice for a variety of applications. New innovations are being developed, focusing on enhancing performance and sustainability. Imagine a mesh that not only filters efficiently but also minimizes waste throughout its lifecycle.

In construction, stainless steel woven wire mesh is becoming a popular choice for architectural facades. Designers are experimenting with different weaves and finishes. These new textures can create stunning visual effects while providing structural support. Filtration systems are also evolving. Advanced designs now allow for improved airflow and water quality. Yet, challenges remain. Not all designs have achieved perfect filtration rates. Continuous research is necessary to push these boundaries further.

Sustainability is a key trend. Manufacturers are exploring recycling options. This could reduce the environmental impact of production. However, practical solutions are still in development. The need for high-quality materials can conflict with eco-friendly practices. As the industry moves forward, the balance between innovation and sustainability will be crucial. The evolution of stainless steel woven wire mesh technology will drive diverse and exciting applications in the coming years.